Sources: Coolbrook B.V., The Netherlands; Cemex S.A.B. de C.V., Monterrey, Mexico; CP staff

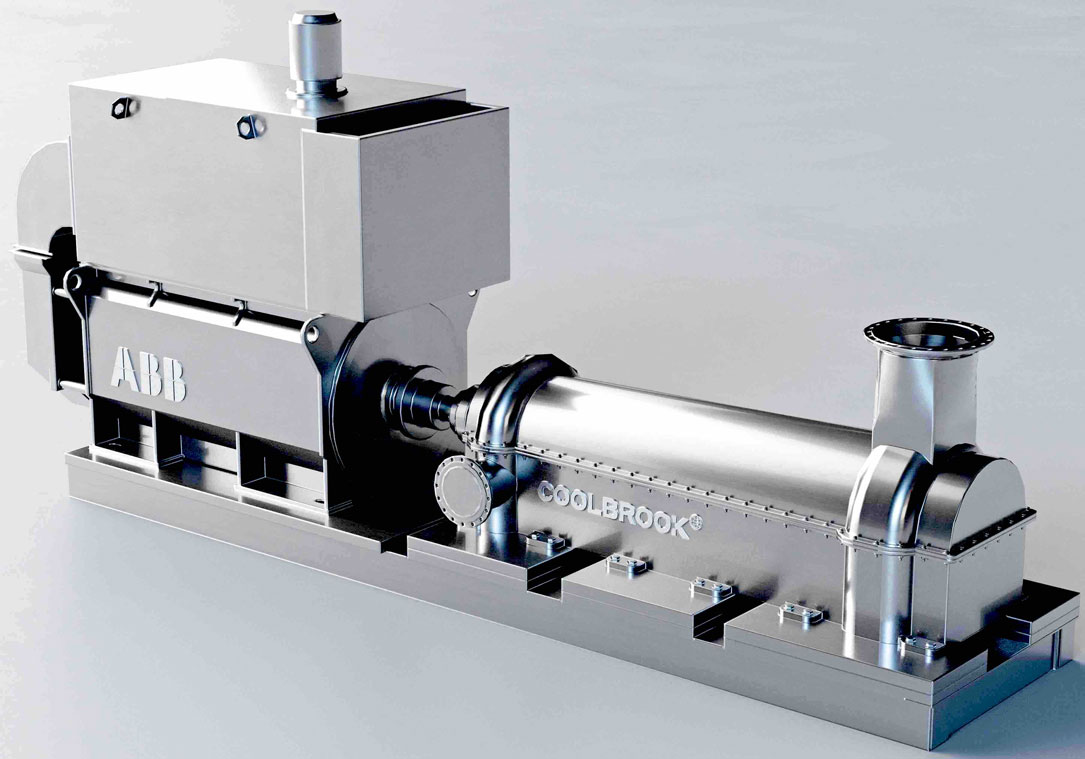

Cemex S.A.B. de C.V. is the first cement producer to announce testing of Coolbrook Roto Dynamic Heater (RDH) technology, which uses electric power to attain the 1,500-1,700°C kiln temperatures required to calcine and convert limestone and other raw feeds to clinker. At plant scale, an RDH apparatus running on renewable energy sources could potentially replace fossil fuel combustion for the kiln phase—cutting the carbon dioxide emissions associated with finished portland cement upwards of 50 percent.

A memorandum of understanding will see Cemex and United Kingdom engineer Coolbrook pursue optimal electric process heating solutions that can be applied in cement production. The companies are evaluating the best production site to test and refine the RDH-based technology, and targeting commercial deployment at industrial scale in 2024. Coolbrook becomes the latest partner in a Cemex research & development undertaking geared to lowering the CO2 factor in the producer’s core output. The RDH is the second renewable energy-powered apparatus the producer plans to test: A demonstration in Spain earlier this year involving solar energy-derived fuel netted a lab-sized specimen of what investigators dubbed the world’s first “solar clinker.”

“The electrification of the heating and calcination process is an important step towards decarbonizing our cement operations,” says Cemex Vice President of Global Operations, Technical and Energy Roberto Ponguta. “To the extent that we can use electricity from renewable sources, we can eliminate carbon emissions related to the heating of cement kilns. We are constantly looking for the best technologies and most promising partnerships to meet our Climate Action targets. Our collaboration with Coolbrook is another example.”

“Coolbrook has set a target to build a comprehensive ecosystem around its revolutionary technology and to test its use in as many industrial processes as fast as possible,” adds Coolbrook Executive Chairman Ilpo Kuokkanen. “Together with Cemex, we can bring the technology to cement production and achieve significant emission reductions in one of the most energy and carbon dioxide-intensive industrial processes.”

Related article

Cemex concentrates solar heat for calcining, clinker production first